If your RC battery connector sparks badly when you plug in, that is not just an annoying pop, it is wear and tear happening right on the terminals. I see this a lot on higher power setups, bigger ESCs, and anything with larger capacitors. The good news is it is usually not a mystery fault, it is inrush current, and you can fix it properly.

If your RC battery connector sparks badly when you plug in, that is not just an annoying pop, it is wear and tear happening right on the terminals. I see this a lot on higher power setups, bigger ESCs, and anything with larger capacitors. The good news is it is usually not a mystery fault, it is inrush current, and you can fix it properly.

What sparking does to your setup over time

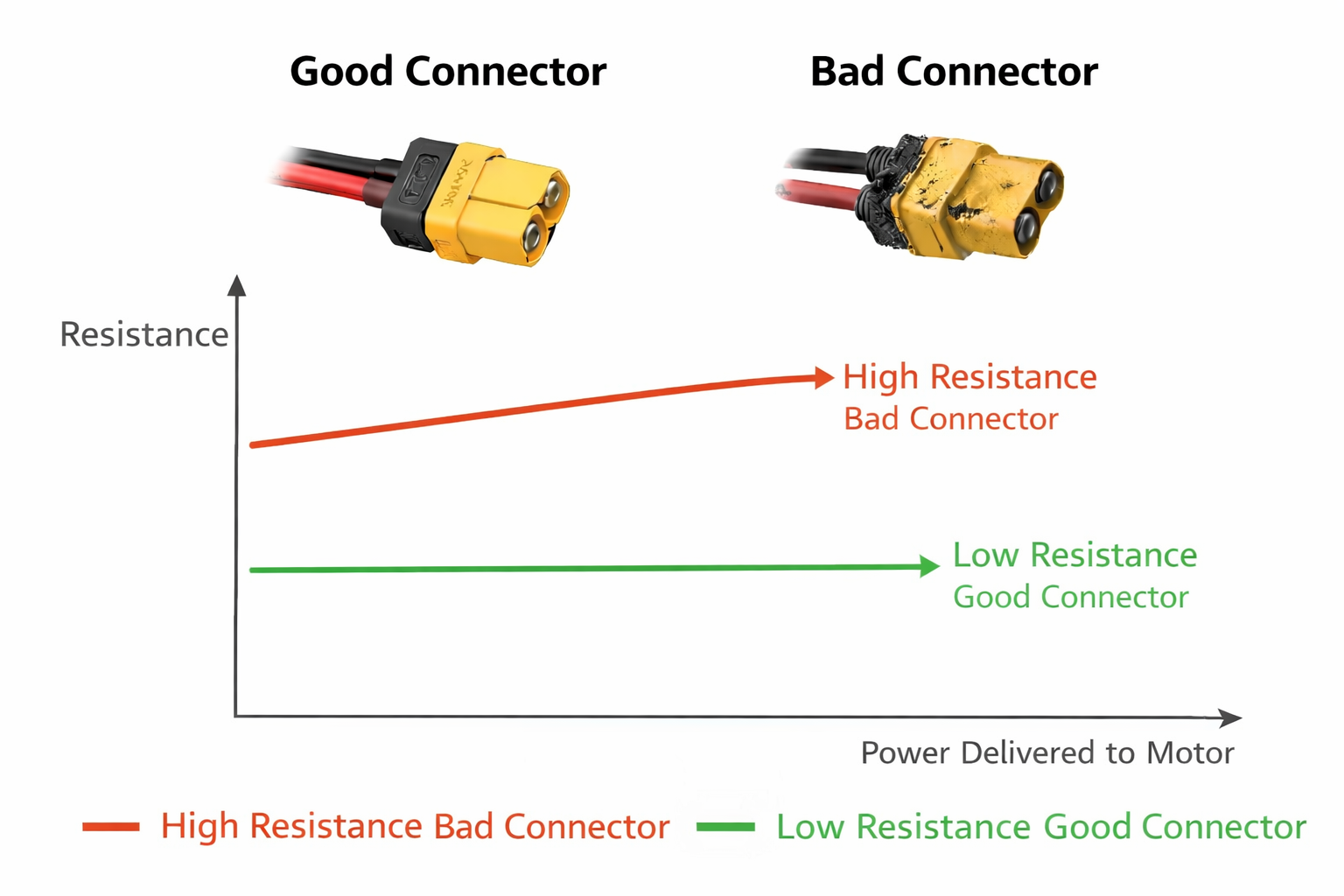

Every time you get that spark, a tiny arc jumps between the metal surfaces. That arc leaves micro pitting and dark carbon marks on the connector. Over time, those marks increase resistance, and resistance is the enemy of performance.

Here is what burnt connectors can cost you

1, More resistance at the plug, which creates more voltage drop under load

2, Less punch and more battery sag, because power is being wasted as heat

3, Hot connectors, softened housings, and weaker grip over time

4, Unreliable connections, random cut outs, or melted plugs on high current models

So even though the spark only lasts a split second, the damage stacks up across many plug in cycles.

Why it sparks, the simple explanation

Most ESCs have capacitors on the input side. When the battery is unplugged, those capacitors are basically empty. The moment you connect the battery, the capacitors try to charge immediately. That creates a very high current draw for a very short moment. This is inrush current, and it is what causes the pop and spark at the connector.

The higher the voltage, and the larger the capacitor bank in the ESC, the harder the spark tends to be.

What you can do about it

There are a few practical steps that make a real difference. Some are good habits, and one is the proper long term hardware fix.

1, The proper fix, use an anti spark connector

If you want the cleanest solution, fit an anti spark connector. The XT90 S anti spark is popular because it is simple, it works, and it is designed to reduce that inrush current spike during connection.

2, Replace connectors that are already burnt or loose

If a connector is blackened, pitted, feels loose, or gets hot, it is already costing you performa

nce. A worn connector can spark more, heat more, and fail under load. Replacing it early is often cheaper than chasing random power issues l

ater.

3, Connect cleanly, fully, and in one motion

Half plugging is where arcing is worst. I always aim to seat the connector smoothly and fully, without hovering at the contact point. Partial contact creates heat quickly, especially at higher current.

4, Make sure the connector rating matches the setup

High current setups need connectors that can handle the load without excessive resistance. Undersized connectors run hotter, wear faster, and can become a bottleneck for power delivery.

5, Use battery connector dust covers

This one is simple but underrated. Battery connector dust covers help keep grit, dust, and metal debris out of the terminals when batteries are stored, transported, or sitting in a flight box. Contamination inside the connector can make sparking worse because the contact surface is no longer clean and smooth.

Dust and debris can cause a few issues

1, Poor contact area, which increases resistance and heat

2, More arcing during connection because the metal surfaces are not mating cleanly

3, Faster wear on the plating, especially if grit gets rubbed into the terminals during plugging in

4, Higher chance of accidental shorts if a battery plug touches something conductive in your bag or toolbox

I like dust covers because they are cheap insurance. They keep connectors cleaner, reduce the rate of wear, and make your power system more reliable over the long term.

Why the XT90 S anti spark works

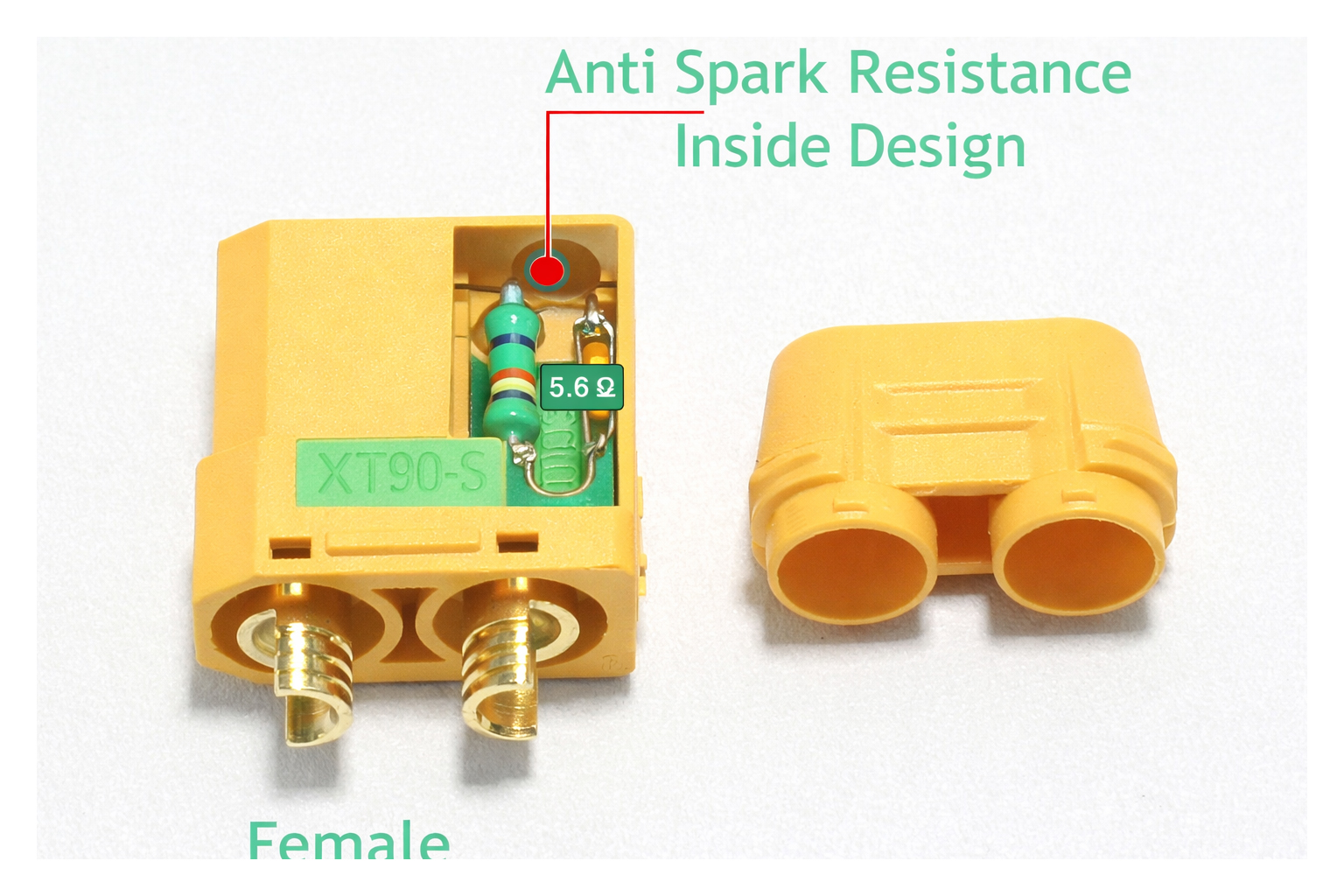

The XT90 S uses

a two stage connection design to pre charge the ESC capacitors before the main terminals fully engage. Inside the female side of the connector there is a small resistor, typically around 5.6 ohms. That resistor is not there to carry the full running current, it is only there for the first moment of connection.

Stage 1, Pre charge

When you start plugging in, the tip of the male pin first makes contact with an isolated metal ring near the entrance of the female socket. That ring is connected to the main terminal through the internal resistor.

Instead of a massive rush of current, the resistor limits the flow to a controlled trickle. This gently charges the ESC capacitors over a few milliseconds, so they are not empty anymore by the time the main contacts engage.

Stage 2, Full connection

As you push the connector fully home, the male pin slides past the resistor ring and makes direct contact with the main gold plated terminal. In the fully seated position the resistor path is bypassed completely, so the connector can deliver full current, typically 90A and above, without extra resistance from the pre charge circuit.

What you should expect after upgrading

In most cases the spark and pop is gone, or dramatically reduced. The connector stays cleaner, the terminals stay smoother, and you avoid that slow creep of added resistance that steals performance. You also reduce the chance of heat damage at the plug on high draw models.

A couple of important notes

An anti spark connector reduces inrush, but it cannot fix every issue. If a connector is already worn, dirty, or loose, it can still arc and heat up. Also, always keep polarity correct and treat battery connections with respect, high current systems can do damage quickly if something shorts.

My takeaway

If your connector sparks badly, the real problem is usually inrush current charging the ESC capacitors instantly. That spark damages the connector over time, increases resistance, creates heat, and wastes power. The simplest long term fix is an anti spark connector like the XT90 S, and good connector habits like using dust covers to keep terminals clean and protected.

Thank you for taking the time to read this article. Should you feel that this article requires an update or should you wish to ask me a question, please do so by emailing james@theflitelab.co.za

James Roney.

Published 6 February 2026